The glass crystallizer is a glass container, which helps the operator. The skillfully and effectively execute the study. It is important to understand what the process of crystallization of a substance means, so it will begin with clarifying the process of crystallization and purification.

Crystallization process

It is the one where crystals of a saturated solute solution are formed, when a substance is cooled from the liquid - gaseous - solid state. First, the solvent is evaporated until saturation is achieved. Second, the solution is cooled or hot solute is added to saturation, then allowed to cool slowly.

Chemically it happens that by increasing the molecular agitation the kinetic energy in the solution is produced. Where the atoms crystallize by settling on the bottom of the container. They are crystalline in color, solid and flat. The process derives advantages such as, the product is generated in a first phase at 99%.

Control is exercised on the realization to produce the uniform crystals. Easy, simple operation and is performed at temperature environment. In the disadvantages we have that not all the solute is recovered, nor is it purifies all the material in the same phase.

Purification process

This is produced at an industrial level and in a targeted way to conducting experiments in laboratories. It's about making a substance or sample is more pure. It means that it does not contain foreign elements, it is not dirty or altered. To get a high degree of purity First, the formation of the crystals that will be small. Second the nucleation and the formation of the layer of crystal or growth.

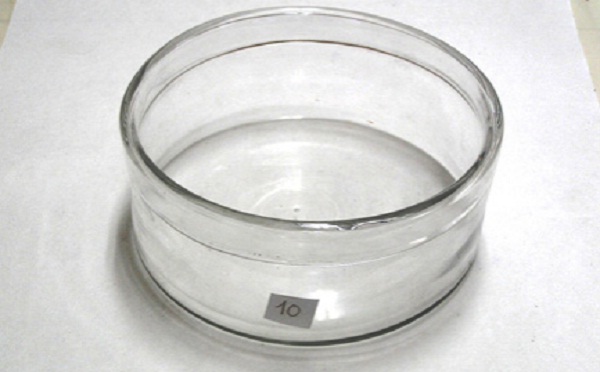

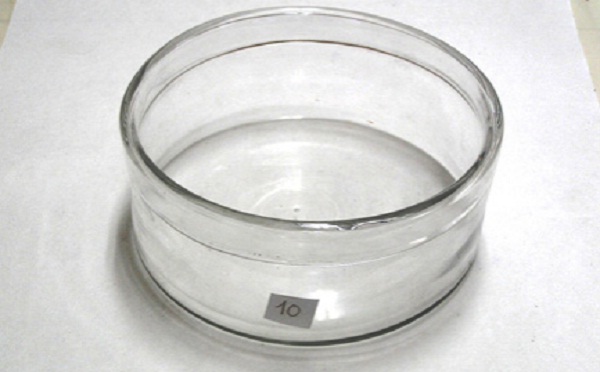

Glass crystallizer which is

It is a laboratory material, which is located as a glass object, constructed of borosilicate, Pyrex, Kimax, Duran. It can be used as a container for containing solutions and as a container lid. The purpose of this object is the crystallization of solutes present in a solution. By means of the evaporation of a liquid, in a simple way.

Within its applications, it is considered that normal techniques should not be performed because its operation is not viable. For already treated solutions with high contamination also does not work. It is a container with a wide mouth and short stature. Its shape is cylindrical and has a thick edge.

Features of glass crystallizer

It is made of chemical elements such as Boron, Silicon called borosilicate, Duran, Pyrex, Kimax.Es a container of low height and has a wide base. As a lid for other containers. Its shape allows the evaporation process to be fast, easy and effective. Withstands high temperatures.

It is resistant to corrosive substances such as hydrochloric, nitric, sulfuric acids. They are of two types with a beak and without a beak. It allows you to easily transfer liquids to other containers. It has very light weight.

Types of glass crystallizer

Two types can be achieved: Without a beak and with a beak. No peak with capacity from 150 mm to 7000 mm, with diameter from 80 mm to 300 mm and with height from 40 mm to 150 mm. With peak capacity from 250 mm to 1500 mm, with diameter from 100 mm to 180 mm and with height from 50 mm to 90 mm.

Glass crystallizer use

It is used to dry, crystallize solids. As a cover of other packaging. To sterilize small objects and also substances. Evaporation of solvents with the aim of obtaining solutes. It's a dryer fast of substances. Allows the solute to form crystals without the introduction of more solvent. It is used as a desktop container where they are placed pipettes, vials of substances of liquids, small funnels,

Glass crystallizer function

It allows evaporation, crystallization or sterilization of certain solutions. It is used in various processes in chemistry and in bilogy. It has resistance to high temperatures. It has the ability to withstand corrosive substances strong acids such as hydrochloric acid, nitric acid, sulfuric acid.

It has a low dilation material that is why it is used in different procedures. A solution is used to make it evaporate. In sterilization by means of steam or in dry air. It is used as a lid or as a container. As a container it can also store harmful substances or pollutants. It does not damage the container it covers.

Glass crystallizer care

The instruments that are normally used in laboratories among others are usually made of glass. Which support various treatment processes, therefore it is necessary the proper use of glass materials especially the crystallizer which can be thin-walled or thick, with thick edge or without it.

Check the quality of the glass when it is going to be used to subject it to heat. Discard those that have been beaten, with stretch marks, with fractures, with factory defects. Do not clean with abrasives as they scratch and weaken in the same way do not wash with wire sponge.Remove from the stove when they are cold.

Do not place it on damp or cold countertops. These care must be taken because it is made of a special glass that when broken. It forms very sharp stipes or fractions. They cause wounds that generate a lot of pain. It is necessary that when handling this element be executed with an asbestos glove or woolen cloth.

If by accident you fall splitting it is necessary to carry safety accessories because incrustations can happen.

Glass crystallizer price

The description will be made according to the type where those without spout (without flange) can be obtained from 300 ml x 100 mm x 50 mm in 6 dollars or 24 euros. with 600 ml x 125 mm x 63 mm at 10.50 euros or 2 dollars. Of 80 ml x 60 mm x 40 mm in 10 dollars or 10 euros. Made of Pyrex glass, with 125mm x 65mm for $581.25.

50mm x 35mm at $240, with 100mm x 50mm two for $340, 70mm x 50mm at $401. For 80 mm x 40 mm for 262,50 made of borosilicate. 125mm x 65mm Without spout (with flange) 500ml x 100mm x 50mm in 12.36 euros.De 1000 ml x 100 mm x 50 mm in 13,94. With 750 ml x 100 mm x 50 mm for 9.36 euros.

Now those who have a beak. Of 1000 ml borosilicate at 10.30 euros. With 300 ml borosilicate for 0 euros. It has 125mm x 50mm in 1063 dollars. From 60 mm in 1010 dollars.

Applications for the glass crystallizer

Its application is wide in many processes to obtain the crystallization of solutes as in the processes of sample analysis in laboratories, for the study of chemical elements that are formed in water, the reduction of environmental pollution, in the manufacture of sugar and ethanol, in the pharmaceutical and cosmetological area.

In the study of food and beverage production, in meteorology, in microbiology, biotechnology, geology, in chemistry, in petrochemistry, in chemical analysis of soil and plants.

Here I leave you the information of glass crystallizer, reasons to know it, which will be useful for you to acquire knowledge and also to answer your assignments.